The Pittsburgh Wall Insulation Experts

Are your walls cold? Is your home drafty? Then we have the right solution for you!

Why Dense Pack Cellulose is the Best Solution for Your Wall Insulation

- Unlike older methods, Dense Pack Cellulose packs so tight that it CANNOT SETTLE. We guarantee it.

- Because it both air seals and insulates your walls, nothing will make your home warmer.

- Cellulose insulation is 100% GREEN and non-toxic.

- No other wall insulation will come close to making your home as quiet as dense-pack cellulose.

- Unlike injection foam, dense-pack cellulose NEVER shrinks or gets brittle and cracks over time.

- Click this link to read a great article about cellulose insulation from the University of Massachusetts’ Construction Science Department.

How Will Dense Pack Exterior Wall Insulation Affect my Homes Energy Efficiency?

How Will Dense Pack Exterior Wall Insulation Affect my Homes Energy Efficiency?

Using dense packed cellulose for your wall insulation needs achieves two big energy-efficiency-improving functions. First it insulates 2×4 stud bays to an approximate R-Value of R-15. This improvement alone dramatically reduces heat loss. But the other thing achieved when cellulose insulation is dense packed into your walls is that it permanently tightens your home’s “air barrier.” This air-sealing characteristic drastically reduces air infiltration year round, further cutting energy loss. The overall impact of insulating your exterior walls with the dense pack cellulose process should be a 20-30% reduction in your utility bills.

Will Dense Pack Wall Insulation Make my Home More Comfortable?

The effect it will have on your home’s comfort will be instant AND dramatic. The first thing you’ll notice is that cold winter drafts will disappear! Densely packed cellulose insulation in your walls creates an impenetrable barrier to cold winter wind gusts. The next thing you will notice that seasonal hot and cold spots will vanish. This not only moderates your home’s interior temperatures, but makes your exterior walls seem as warm and cozy as your interior walls!

How Does it Work?

When installing cellulose insulation via the dense pack method, one 2″ diameter access hole is drilled at the base of each stud bay in your wall (about every 16″ inches). A fill- tube is then inserted into the access hole and fed into the bay until it hits the top of the wall. Our powerful machine is then turned on, forcing the insulation to literally “flow” around obstructions like wires, outlet boxes, and plumbing pipes, as well as into the small holes, cracks, and access points in your wall. When the fill-tube is finally removed from the bay, the insulation inside is packed so tightly that your fingers cannot poke through it! This is how dense pack cellulose insulates AND reduces air infiltration into your home! When the work is complete, all access holes are sealed / patched and siding is replaced if work is done from the outside.

When installing cellulose insulation via the dense pack method, one 2″ diameter access hole is drilled at the base of each stud bay in your wall (about every 16″ inches). A fill- tube is then inserted into the access hole and fed into the bay until it hits the top of the wall. Our powerful machine is then turned on, forcing the insulation to literally “flow” around obstructions like wires, outlet boxes, and plumbing pipes, as well as into the small holes, cracks, and access points in your wall. When the fill-tube is finally removed from the bay, the insulation inside is packed so tightly that your fingers cannot poke through it! This is how dense pack cellulose insulates AND reduces air infiltration into your home! When the work is complete, all access holes are sealed / patched and siding is replaced if work is done from the outside.

Click the image below to see a short video comparing dense pack cellulose to injection foam for use as wall insulation (or closed cavity insulation).

Why Has Dense-Pack Cellulose Become the Established Wall Insulation Leader for Existing Homes?

Dense pack cellulose has become the established leader, among building science professionals and energy auditors, because of its relentlessly tested and proven track record. According to David Keefe of Home Energy Magazine, “The air sealing benefits can be impressive. It is not unusual to reduce overall house leakage by 30% to 50% by dense-packing walls and other closed-in cavities.” It is also incredibly “green,” non-toxic, and installs reliably every time.

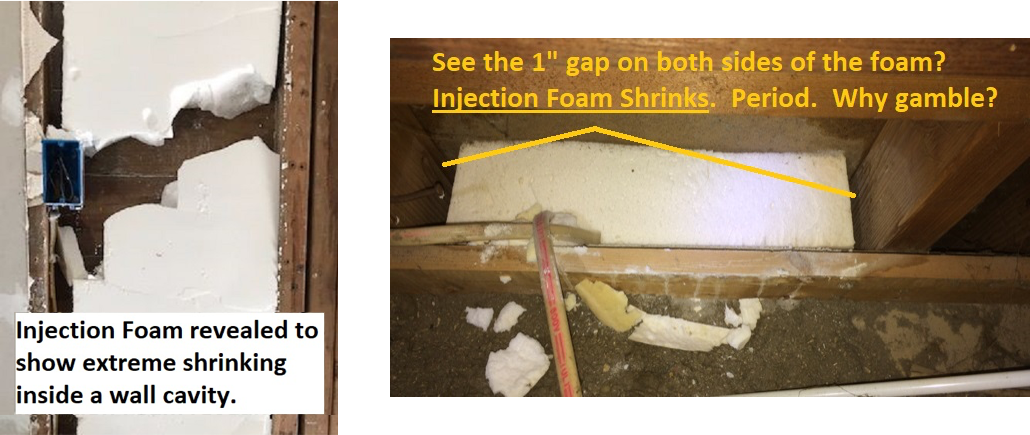

Why We Do Not Use Injection Foam

Injection has widely understood and documented problems. Firstly, due to its chemical make-up of being water based, injection foam has a known tendency to shrink, in some instances badly. The injection foams that are used in Pittsburgh are unproven over time, expensive and highly prone to shrinkage. When I first got started as an insulator I actually worked for two companies doing injection foam (Retrofoam of Michigan & Ecofoam Insulators).

However, after installing the product for 3 months I decided not to use it with my own business due to the shrinkage issues I personally witnessed as well as its significant expense. I was afraid that I’d eventually be sued if I installed injection foam into people’s walls. Unlike the spray foams commonly seen on TV, injection foams are water-based, not polyurethane-based.

See the photos below to see what can happen to injection foam in your walls over time. The first thing that occurs is the super dry, old studs in the wall suck the moisture from the foam, causing it to shrink away from the wall. The resulting gaps that open up then allow airflow and convection currents to develop, sharply reducing its effectiveness.

Foams like Tripolymer foam have not been subjected to nearly the degree of testing within the building science community that dense-pack cellulose and spray polyurethane foam have been. So why choose something that is both expensive and untested if you can choose an insulation (cellulose) and method (dense packing) that is less expensive, greener, and preferred by most building scientists and energy auditors across the United States?

Two Story Colonial Home

Two Story Colonial Home 1950’s Ranch Style Home

1950’s Ranch Style Home Two Story Contemporary Home

Two Story Contemporary Home Modern Patio Home

Modern Patio Home Three Story Home

Three Story Home Cape Cod Home

Cape Cod Home Attic Insulation

Attic Insulation Floor Insulation (Garage Ceiling)

Floor Insulation (Garage Ceiling) Wall Insulation

Wall Insulation Basement Insulation

Basement Insulation Air Leak Sealing

Air Leak Sealing