Welcome to Insulwise’s case study pages!

Creating case studies for specific types of homes is not only unique to Pittsburgh, but the insulation industry in general. What gives us the confidence that we can achieve these types of results? Two things:

- The experience that comes with having insulated over 5,000 homes in the area since 2008.

- Our use of applied building science principles that comes from the owner, Andrew Haak’s, background as an energy auditor and credentialed building performance analyst (from the Building Performance Institute, BPI).

Insulation Case Study: 1950’s Ranch Style Home in Pittsburgh, PA

Background:

The problem for Marguerite S. was that during the summer her ranch style home heated up quickly during the day, causing their air conditioner to run non-stop to keep the home cool (see our short Summertime Syndrome Cartoon to see how Insulwise solves heat related issues in homes). During the winter it was the same problem. The furnace had to run almost constantly to keep the home warm, and their heating bills and cooling bills were both higher than desired!

Energy Efficiency & Comfort Enhancements Completed:

- Air sealed the entire attic floor.

- Built box around pull down ladder, with removable, R-10 insulated lid. Click here for video on how Insulwise builds insulated boxes pull down ladders.

- Built raised storage pad for odds & ends. Click here for video on how Insulwise builds raised attic storage pads.

- Improved attic insulation to R-49 rating with 12” inches of blown in cellulose insulation.

Home’s Problems & Solutions:

We performed a free air infiltration test (using a blower door device) during our initial visit. We found that the home had numerous air leaks in the attic space, and that there was only about 3” inches of insulation. There was also a pull down ladder that was un-insulated and did not seal well. Lastly, like most ranch homes in Pittsburgh, this one had “bulkheads” in the kitchen area. These are lowered ceilings above the cabinets. The special problem they create is that the tops of the walls are completely open to the attic space, allowing substantial air leakage and convective heat loss.

We performed a free air infiltration test (using a blower door device) during our initial visit. We found that the home had numerous air leaks in the attic space, and that there was only about 3” inches of insulation. There was also a pull down ladder that was un-insulated and did not seal well. Lastly, like most ranch homes in Pittsburgh, this one had “bulkheads” in the kitchen area. These are lowered ceilings above the cabinets. The special problem they create is that the tops of the walls are completely open to the attic space, allowing substantial air leakage and convective heat loss.

How did the Issues get Fixed?:

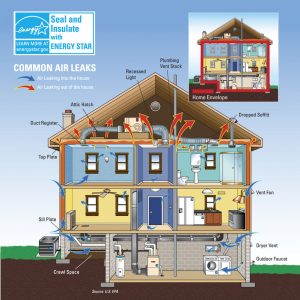

We first set about air sealing the attic floor with spray foam. When any home is heated during the winter, a physical process known as “Stack Effect” occurs. Essentially, the heated air from your furnace rises and then escapes out the top of the home through lots of hidden penetrations. Then cold, dry air gets sucked into the base of the home to replace the air getting lost out the top.

We first set about air sealing the attic floor with spray foam. When any home is heated during the winter, a physical process known as “Stack Effect” occurs. Essentially, the heated air from your furnace rises and then escapes out the top of the home through lots of hidden penetrations. Then cold, dry air gets sucked into the base of the home to replace the air getting lost out the top.

When we air seal an attic deck, we first track down and seal all of the hidden air leaks (wire holes, around every plumbing pipe, on both sides of wall plates, all ceiling fixtures, around bathroom fans, etc). With a ranch, we also have to seal off the tops of the kitchen bulk heads.

When we air seal an attic deck, we first track down and seal all of the hidden air leaks (wire holes, around every plumbing pipe, on both sides of wall plates, all ceiling fixtures, around bathroom fans, etc). With a ranch, we also have to seal off the tops of the kitchen bulk heads.

To make sure the pull-down ladder area was insulated as well as air sealed, we built a wall around it then created a lip for a 2” inch thick piece of R-10 rated foam board to sit on. This forms an insulated, easily moveable, air tight seal over your pull down ladder. Lastly we built a raised storage platform so Marguerite could store her things and installed ventilation baffles in the eaves.

To make sure the pull-down ladder area was insulated as well as air sealed, we built a wall around it then created a lip for a 2” inch thick piece of R-10 rated foam board to sit on. This forms an insulated, easily moveable, air tight seal over your pull down ladder. Lastly we built a raised storage platform so Marguerite could store her things and installed ventilation baffles in the eaves.

Lastly, we added 12” inches of blown in cellulose insulation to achieve a uniform R-49 insulation layer.

How About The Results?

When finished, we performed another blower door test. We found that we had reduced the home’s air infiltration by 28% which was an excellent result (just by working in the attic!). This was the equivalent of shutting a medium-sized window that had been open year round! The heating and cooling bills went down by an average of 25-30%, and the home was much more comfortable year round! As you can see from her review on Angie’s List, the homeowner was thrilled with the results.

“Insulwise Energy & Comfort Solutions removed the last few things from our attic that were too heavy for us to carry. They covered the carpeting with drop-cloths and the crew (3 men) went into the attic and began to prep by spray insulting all of the air space in the ceiling of the entire house with meticulous care. Though this job looked tedious, the men were very thorough. The next step was adding baffles about every 3 areas of roof joists from the vents of the soffit up the grade of the roof about 3 feet (to allow air in the roof, but not into the rooms below. They insulated the areas around the base of those baffles individually.

All of the light fixtures were insulated to allow no air flow to the rooms below and the canister lights were boxed with a special material to accommodate the heat from the light but not to allow air flow. Next an 8″ high hatch was built around the area of the pull down attic access ladder, then an 8″ framing to accommodate the 3 sheets of decking that would give storage space once the insulation was finished. This process took about 7 hours. The next thing was adding the actual insulation material (cellulose, which is a recycled paper material, flame treated and highly rated). The insulation was sprayed in 12″ thick, the deck

All of the light fixtures were insulated to allow no air flow to the rooms below and the canister lights were boxed with a special material to accommodate the heat from the light but not to allow air flow. Next an 8″ high hatch was built around the area of the pull down attic access ladder, then an 8″ framing to accommodate the 3 sheets of decking that would give storage space once the insulation was finished. This process took about 7 hours. The next thing was adding the actual insulation material (cellulose, which is a recycled paper material, flame treated and highly rated). The insulation was sprayed in 12″ thick, the deck

installed and then the men vacuumed everything. A 2″ thick very dense foam hatch cover was placed in the weather sealed hatch. Our attic was rated about R4 before the project. Now is it R49.”

“Andy and the crew are excellent. They called when they were on the way to have us move cars from the driveway in order to not block access for us all day. When they arrived they greeted us, introduced us to the crew and went straight to work. We have already noticed that our air conditioning does not turn on as often and the house is cool. It is also much quieter-we live on a main road with lots of traffic. We are very happy with the work done and would highly recommend Insulwise for any insulation needs.”

Cost:

We do not include costs for our jobs here because of the many variables involved in pricing each home. We typically estimate a payback time of 2-5 years for most homes that we work on, given the substantial reductions in energy bills that most often result from our work! So call us today for a free energy and comfort analysis of your home!

Two Story Colonial Home

Two Story Colonial Home 1950’s Ranch Style Home

1950’s Ranch Style Home Two Story Contemporary Home

Two Story Contemporary Home Modern Patio Home

Modern Patio Home Three Story Home

Three Story Home Cape Cod Home

Cape Cod Home Attic Insulation

Attic Insulation Floor Insulation (Garage Ceiling)

Floor Insulation (Garage Ceiling) Wall Insulation

Wall Insulation Basement Insulation

Basement Insulation Air Leak Sealing

Air Leak Sealing